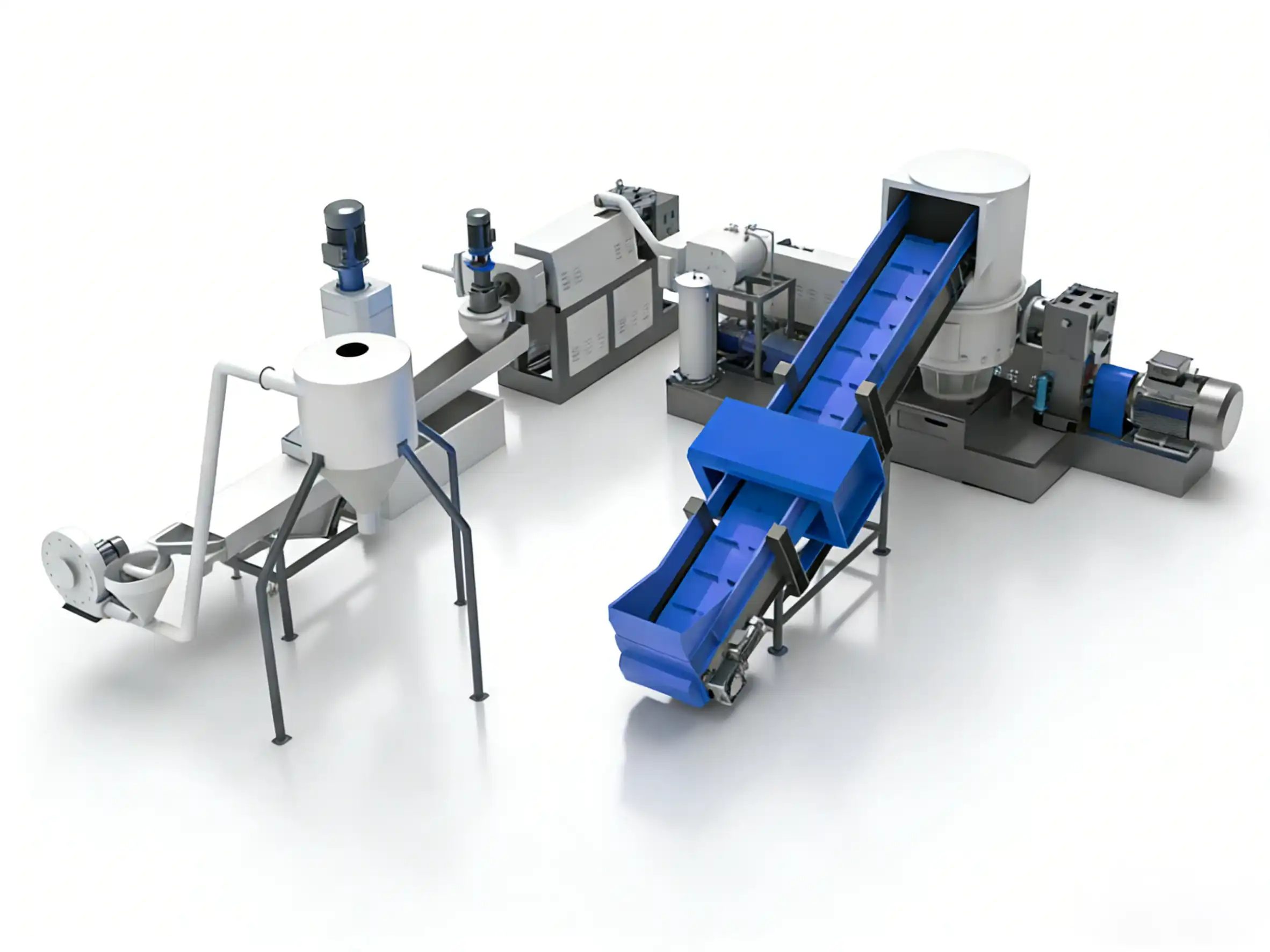

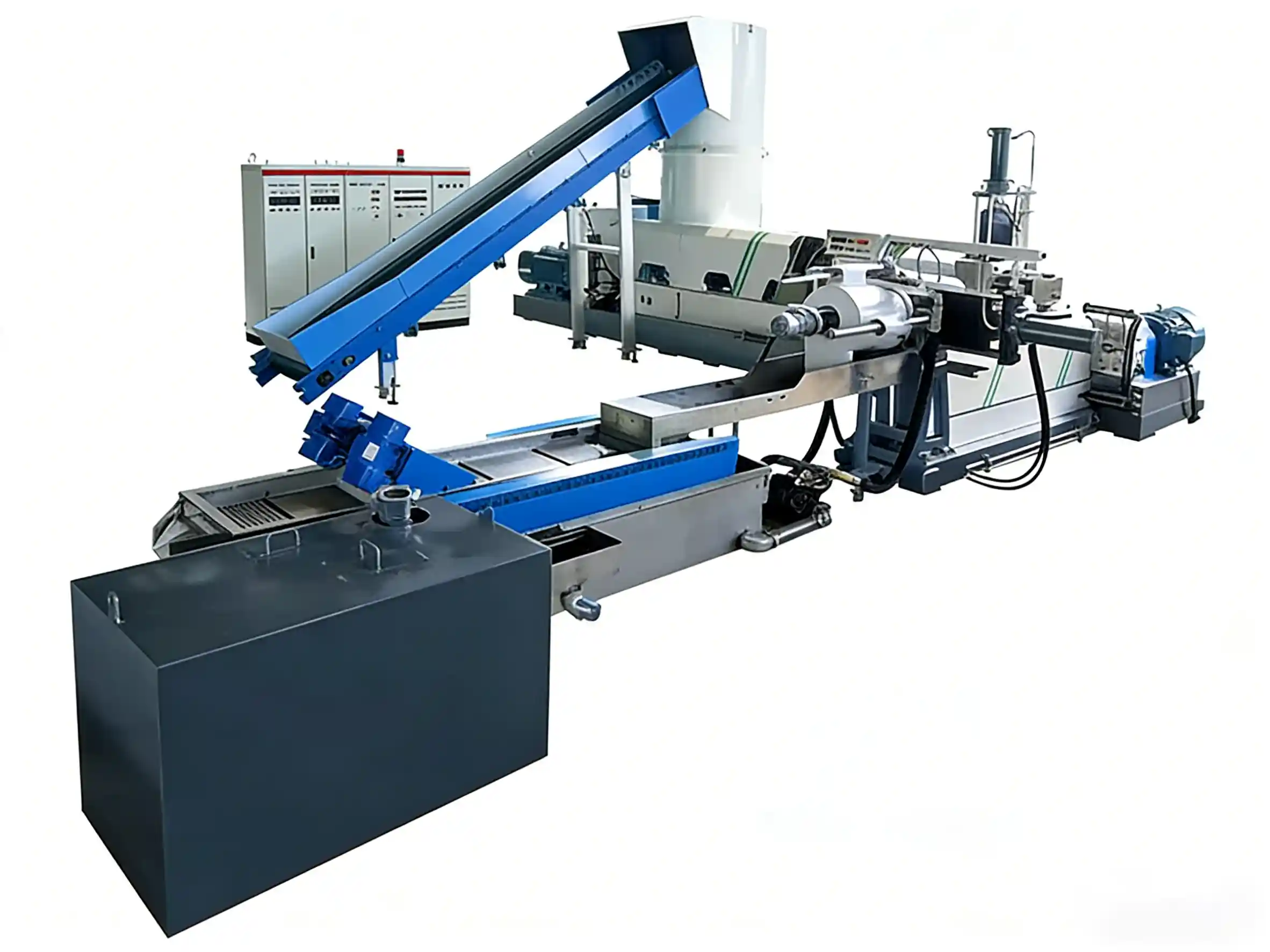

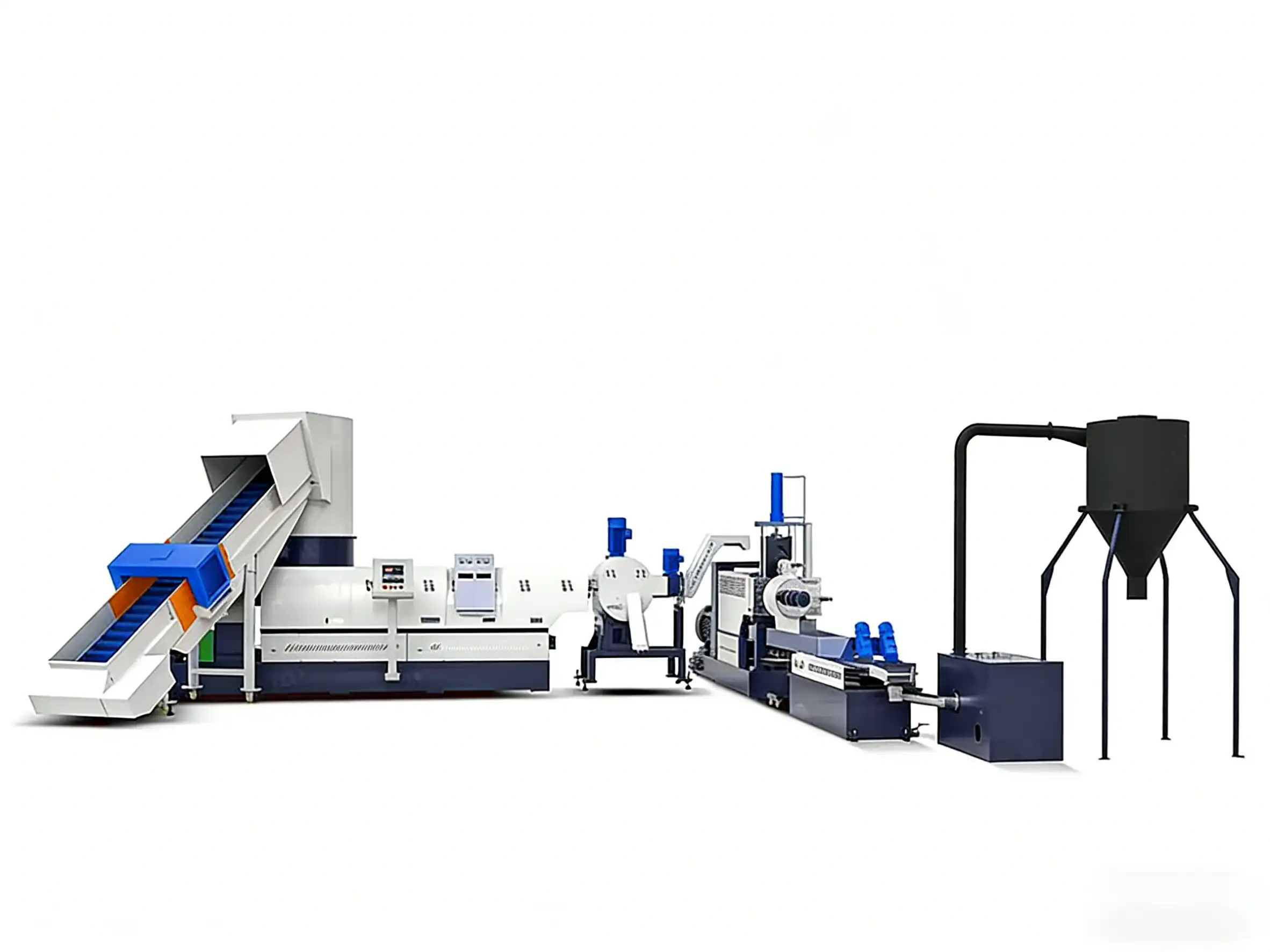

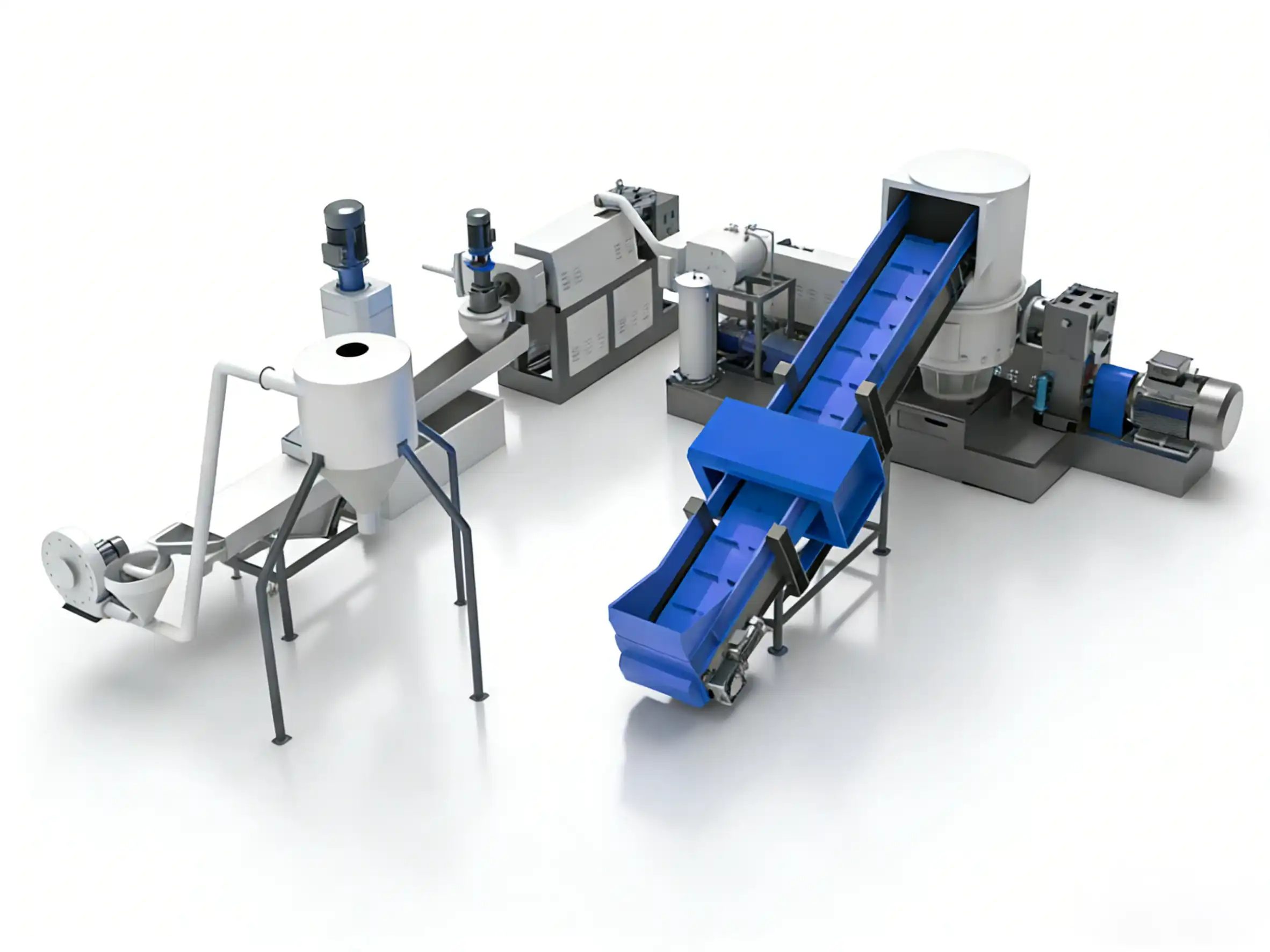

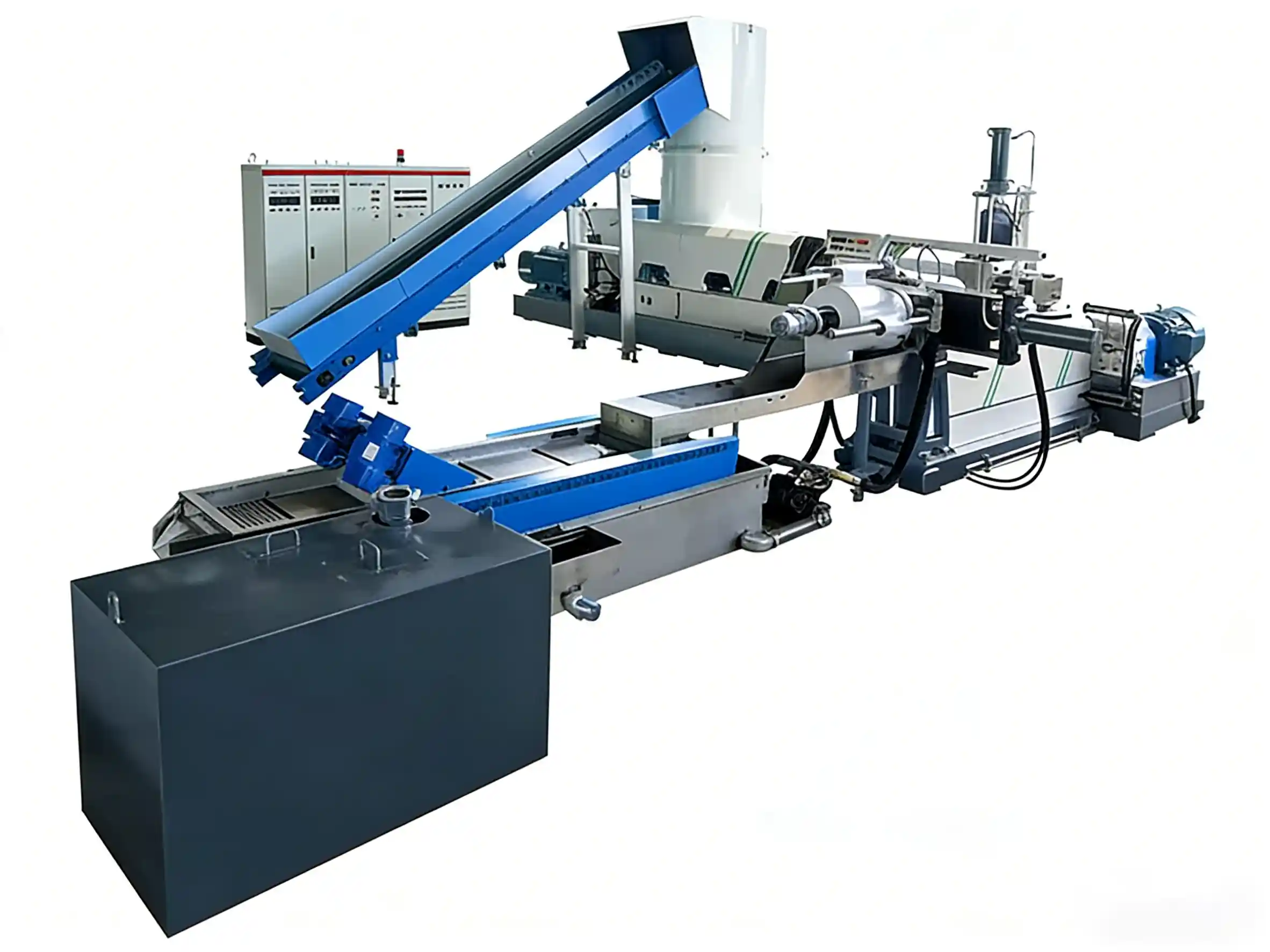

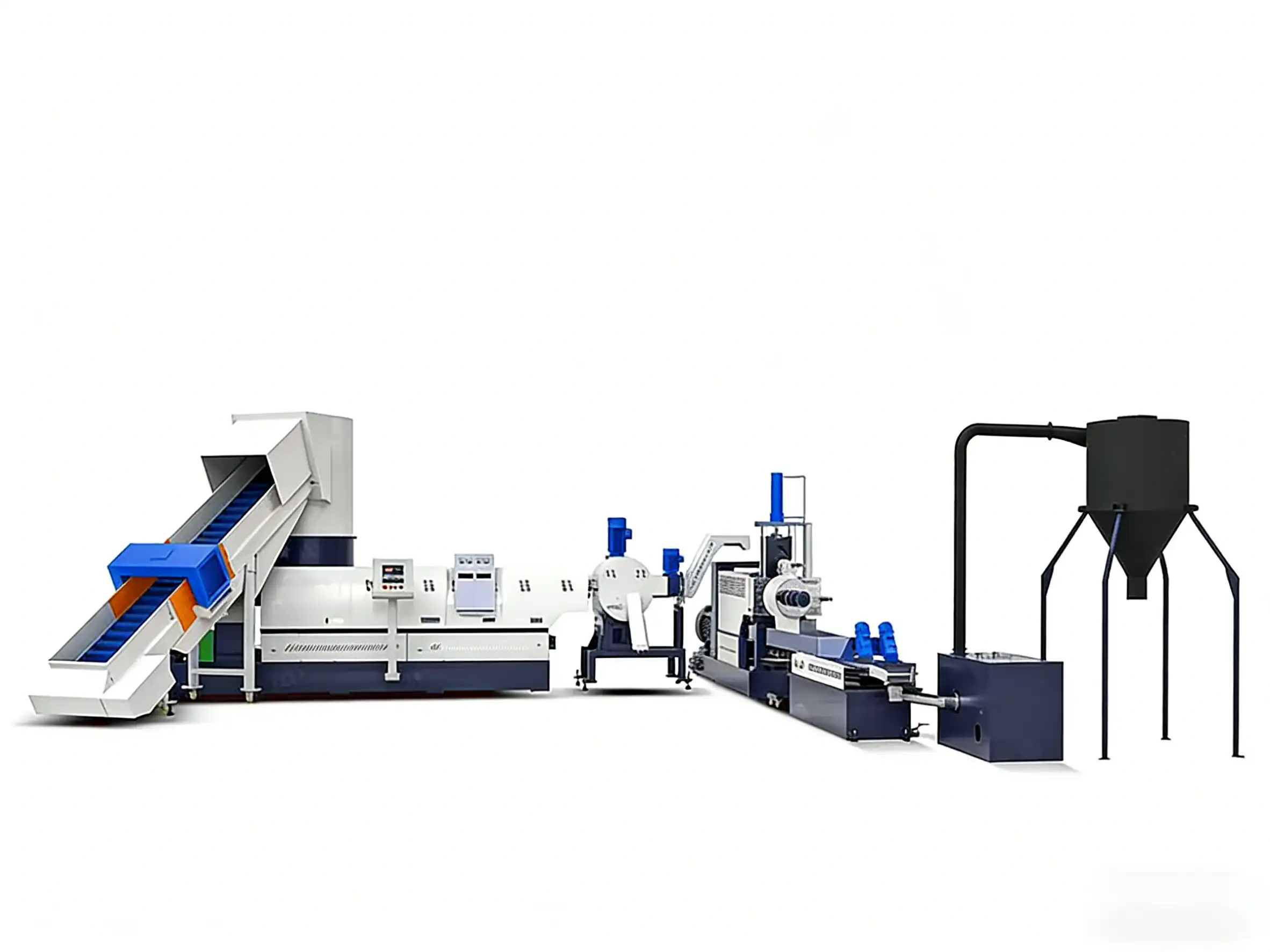

Double-Stage Cutter-Compactor Pelletizing Line

Designed for PE / PP Film Recycling with Stable Output & Low Moisture. The double-stage cutter-compactor pelletizing line combines two-stage cutting and compacting with parallel twin-screw extrusion for superior throughput and pellet quality. Ideal for film, woven bags, PE/PP regrinds and HDPE bottle/jar waste.

Materials Available for Processing

PE Film

PE Film

Woven Bags

Woven Bags

PE/PP Regrinds

PE/PP Regrinds

Clean Pellets

Clean Pellets

Parameter Overview

| Model | Main Motor Power | Capacity | Screw L/D | Cooling | Cutting | Heating Zones | Voltage | Dimension (L×W×H) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| ACS-HD-80 | 55 kW | 200–350 kg/h | 36–42 | Water cooling | Water ring | 6 | 380V 50Hz | 10×2.5×3 m | ~6500 kg |

| ACS-HD-100 | 90 kW | 350–550 kg/h | 36–42 | Water cooling | Water ring | 6 | 380V 50Hz | 12×2.8×3.2 m | ~9000 kg |

| ACS-HD-120 | 132 kW | 550–800 kg/h | 36–42 | Water cooling | Water ring | 7 | 380V 50Hz | 14×3×3.5 m | ~12000 kg |

| ACS-HD-140 | 160 kW | 800–1200 kg/h | 36–42 | Water cooling | Water ring | 7 | 380V 50Hz | 16×3.2×3.8 m | ~15000 kg |

| ACS-HD-160 | 200 kW | 1200–1600 kg/h | 36–42 | Water cooling | Water ring | 8 | 380V 50Hz | 18×3.5×4 m | ~18000 kg |

* Specifications may vary based on raw material condition and customer requirements.

Brief Description of Pelletizing Process

Pelletizing Line Detail Photos

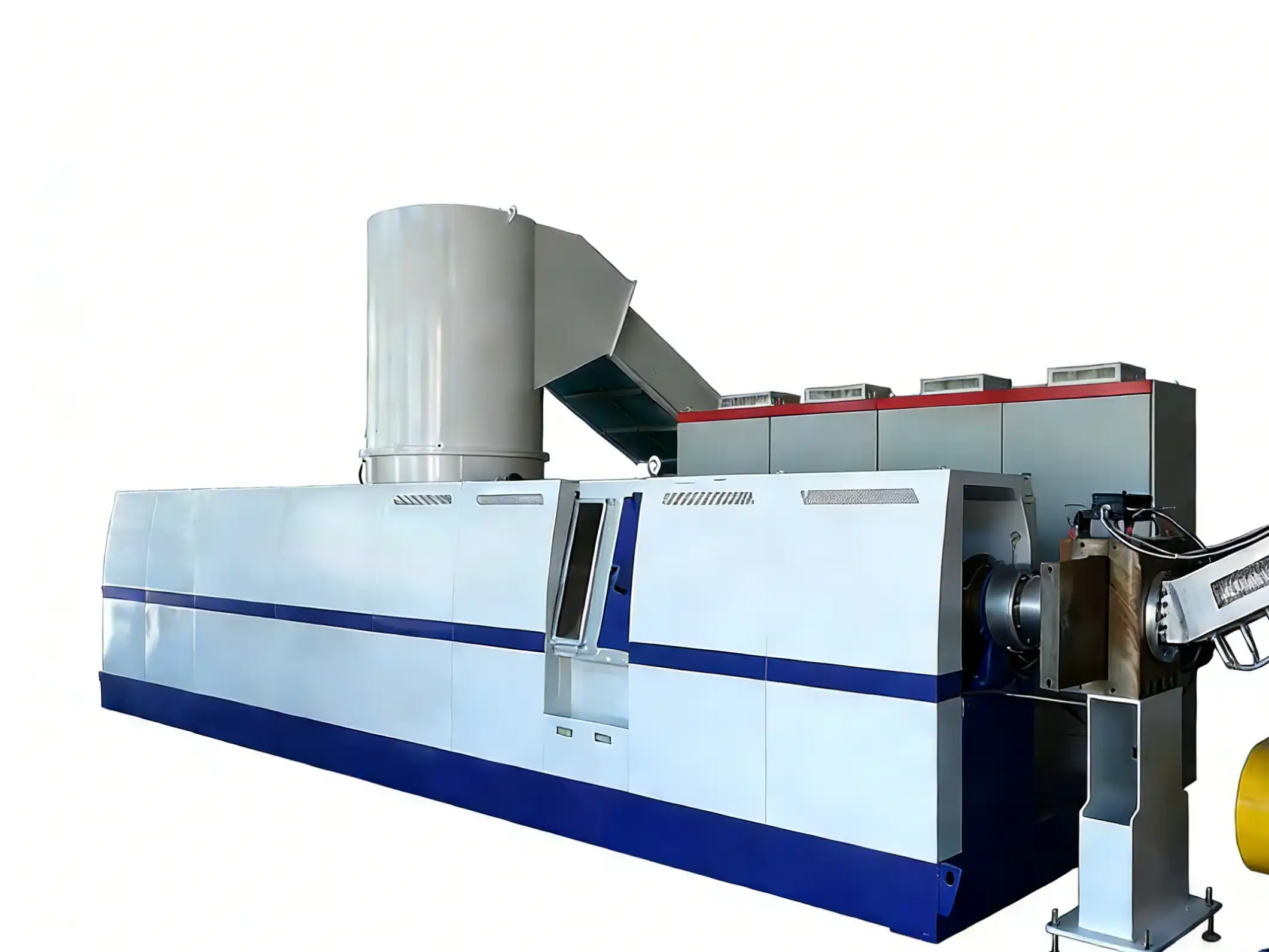

Cutter Compactor

Extruder

Second Extruder

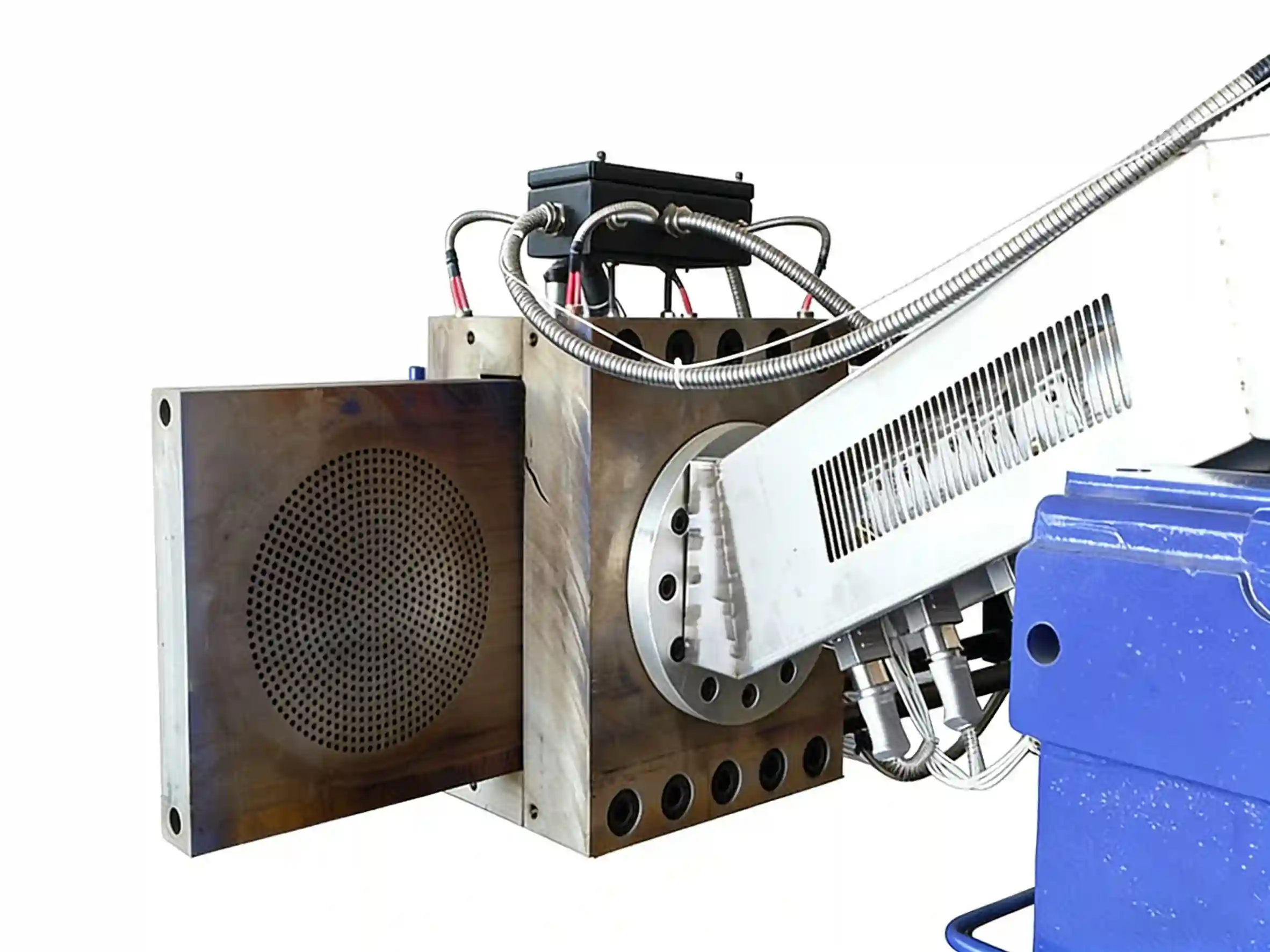

Meshless Drain Filter

Water Ring Cutter

Vertical Dehydrator

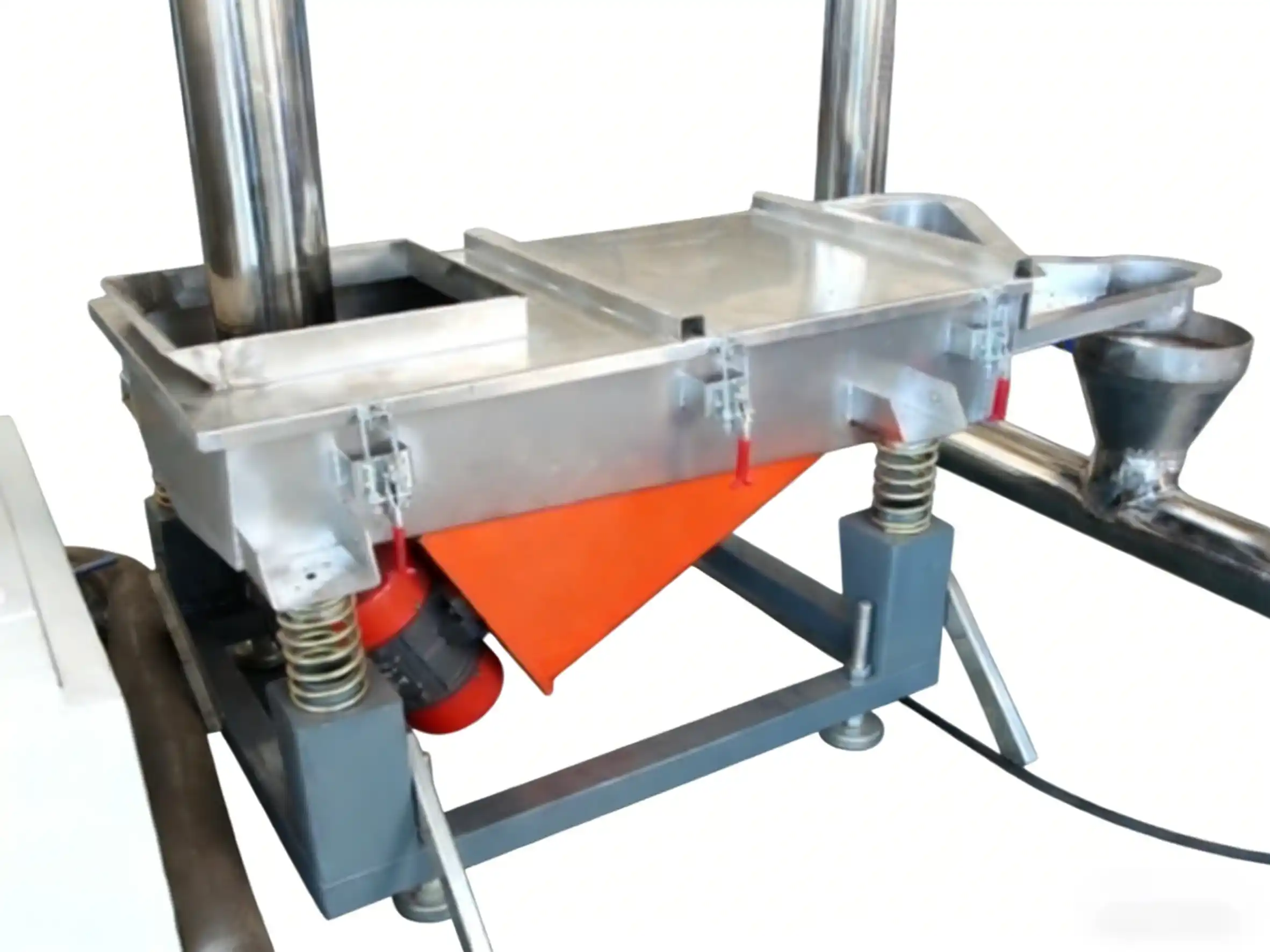

Vibrating Sieve

Silo

Control Cabinet

Complete Double-Stage Pelletizing Line in Operation

Watch our double-stage cutter-compactor pelletizing line running at full capacity. See how we process PE/PP film and regrinds into stable, high-quality pellets for your recycling business.

Request A Free Quote

We'd Like To Work With You. Get a customized solution for your pelletizing project.

15+ Years Experience

Professional plastic recycling solutions

50+ Countries Served

Global installation and support

24–48h Response

Fast engineering support

Get Your Free Quote

Tell us your material and capacity — our engineers will recommend the right configuration.