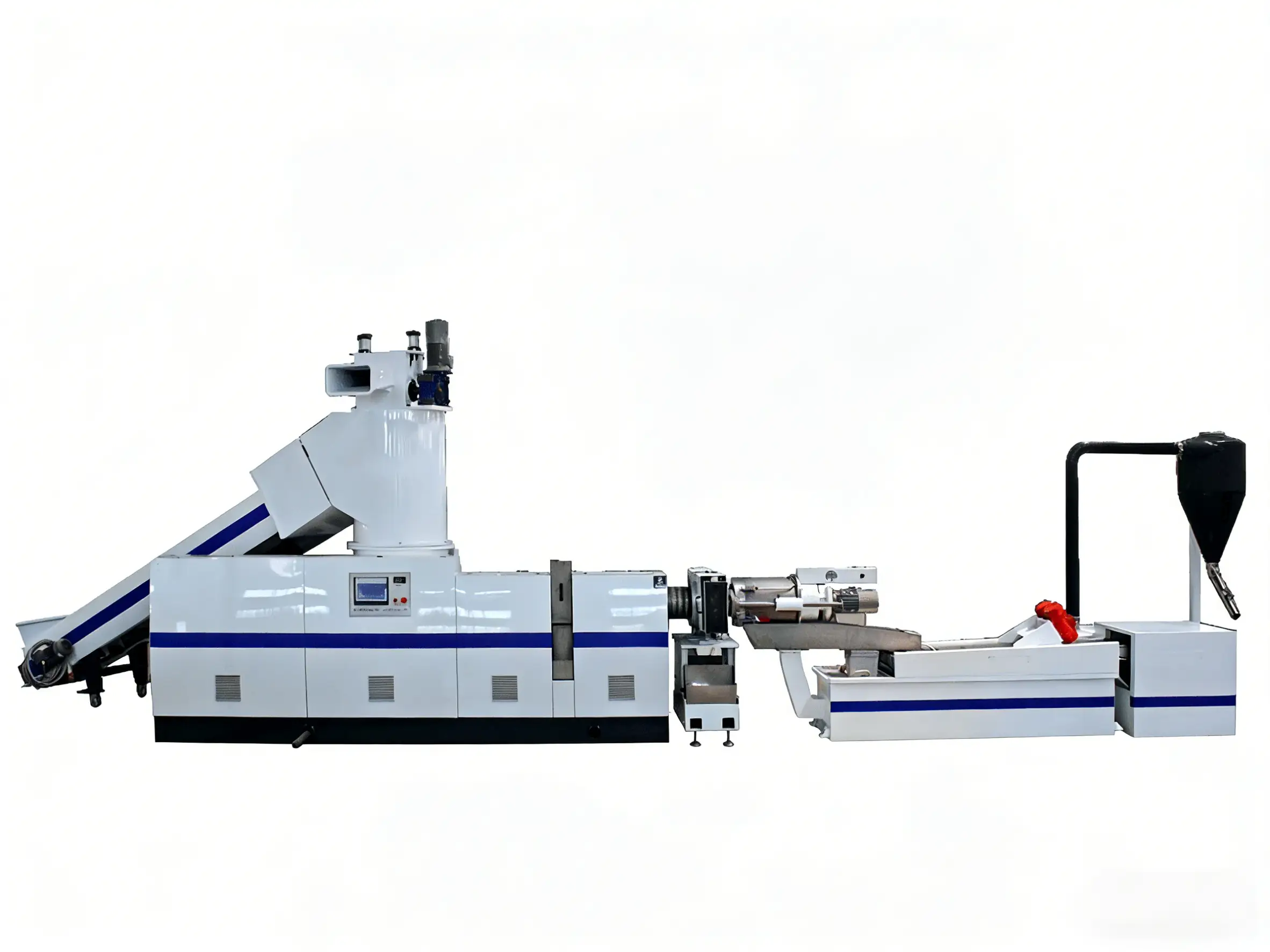

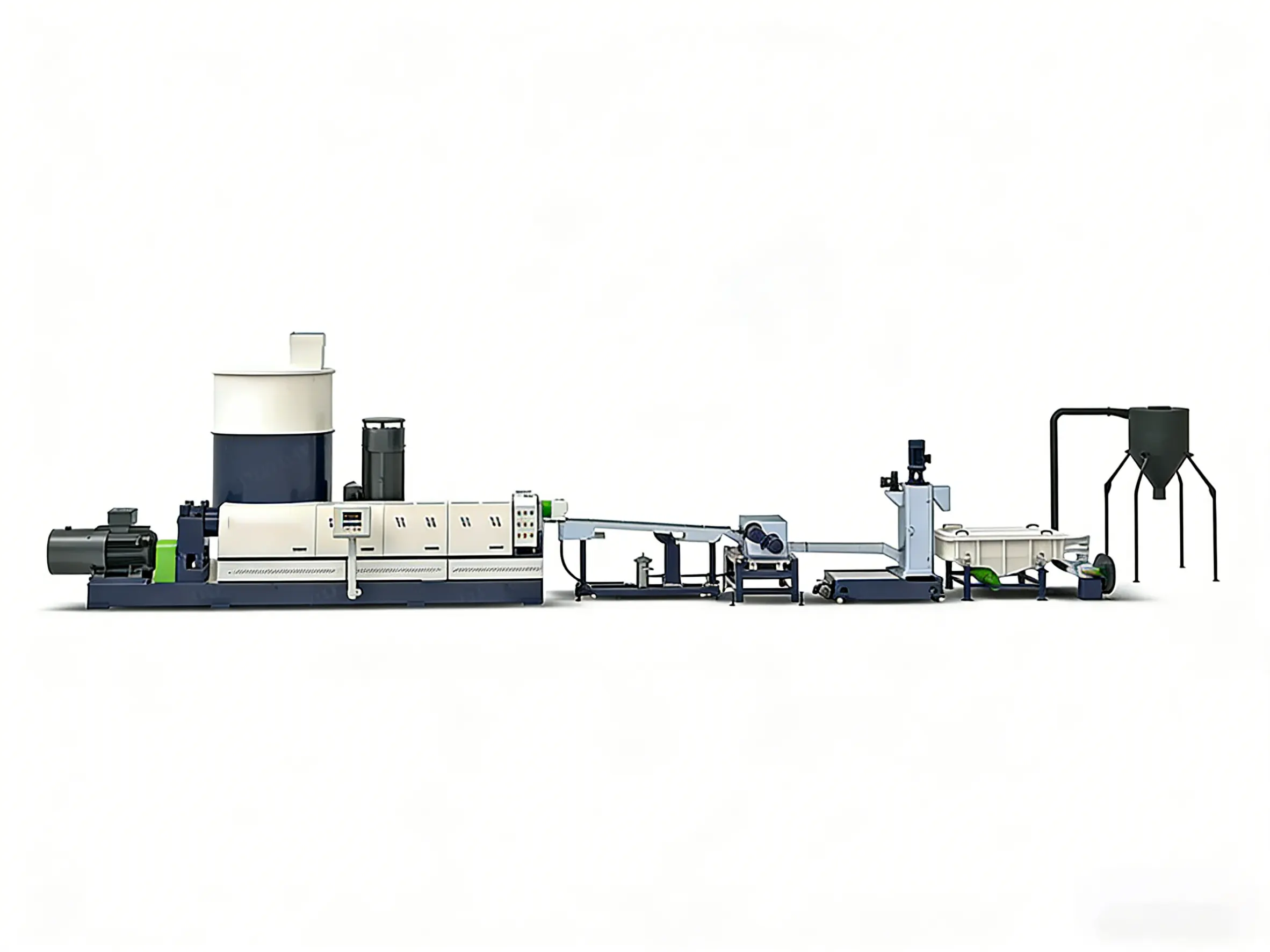

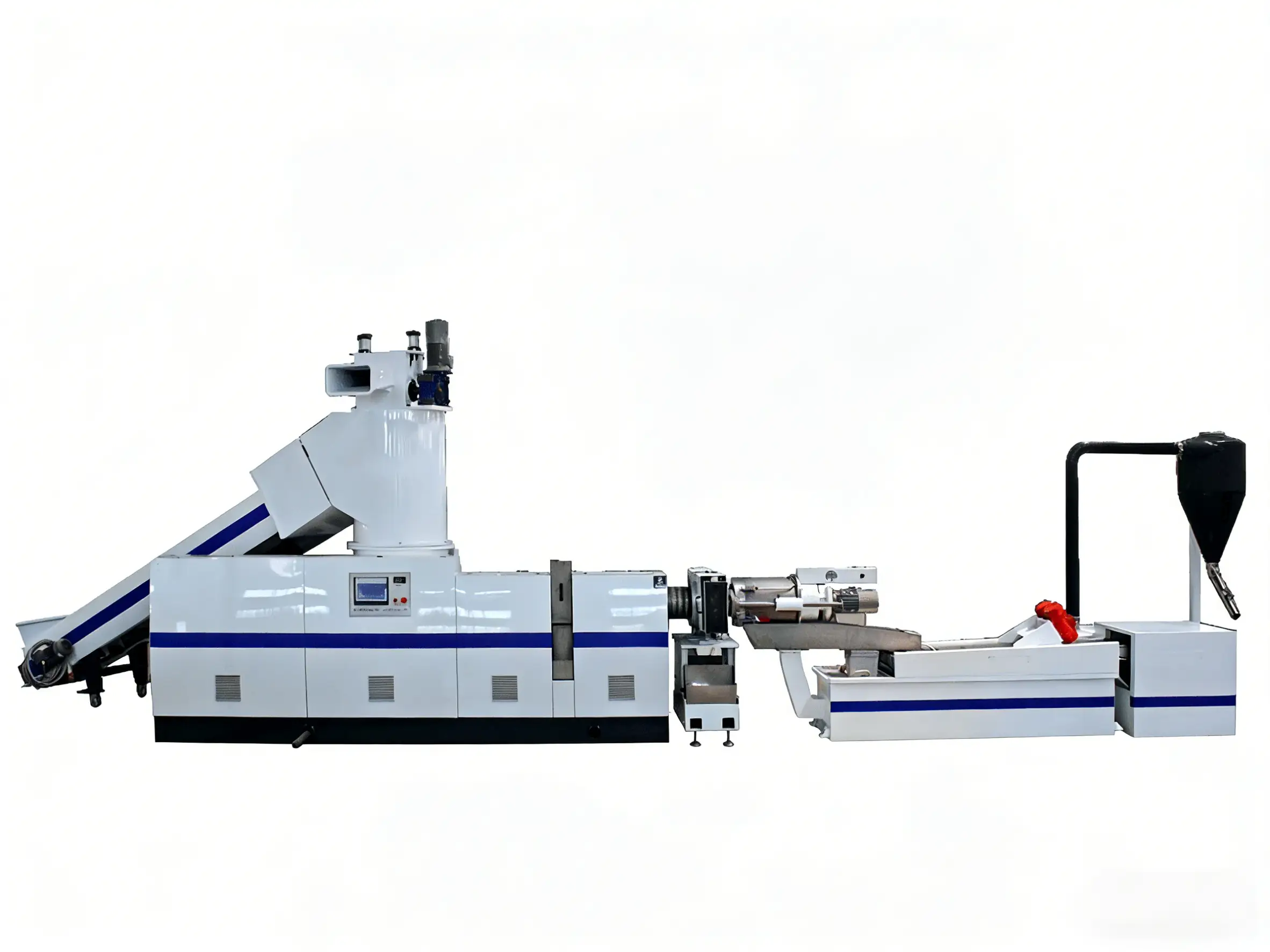

PET Flakes Dedicated Pelletizing Line

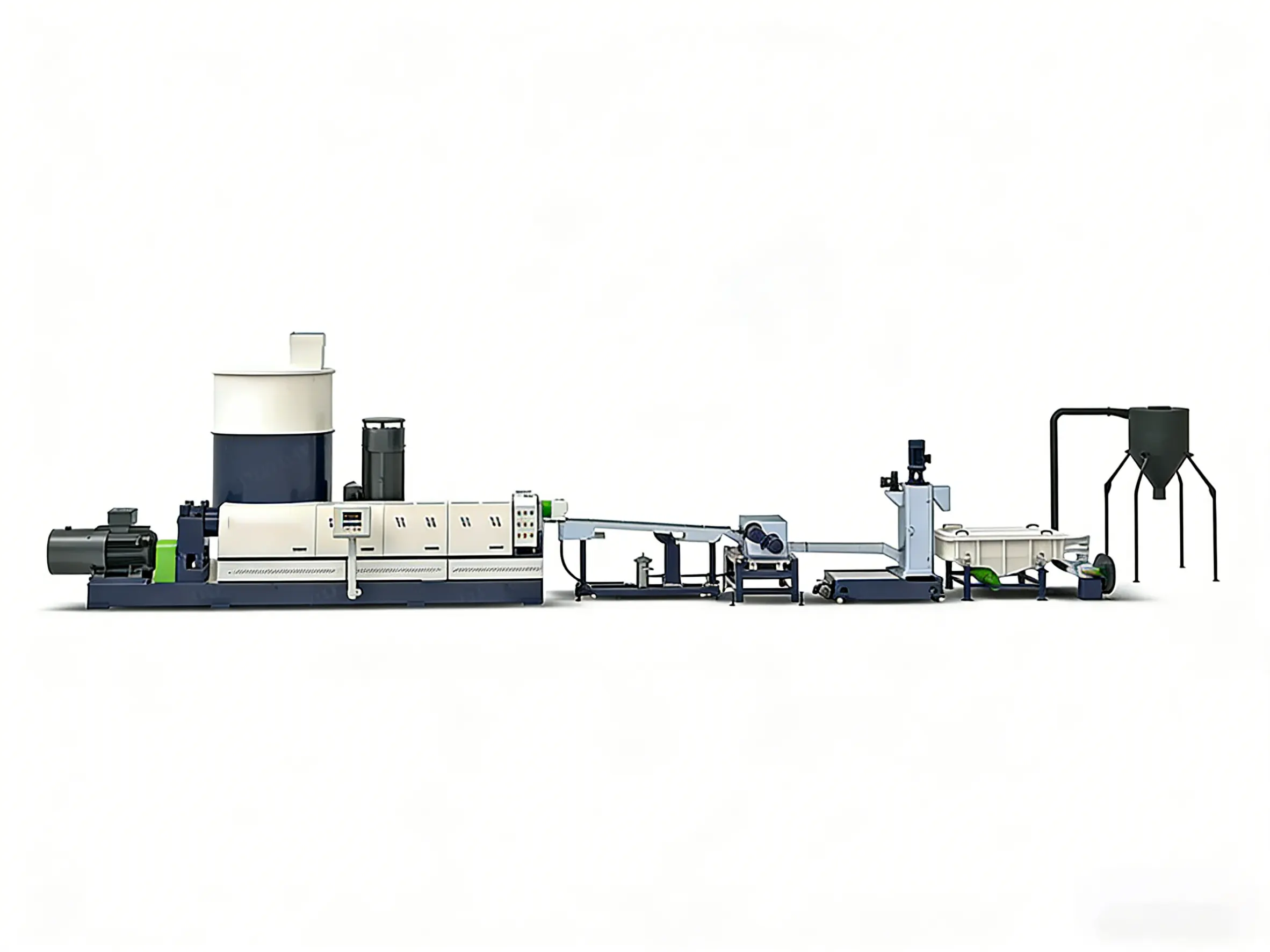

Specialized pelletizing system for Polyethylene Terephthalate with IV retention and crystallization for high-quality rPET pellets. Underwater die-face cutting delivers uniform pellets for food-grade and fiber applications.

Materials Available for Processing

PET Flakes

PET Flakes Post-Wash PET

Post-Wash PET rPET Regrinds

rPET Regrinds rPET Pellets

rPET PelletsParameter Overview

| Model | Capacity (kg/h) | IV Retention | Pellet Size | Power (kW) | Voltage |

|---|---|---|---|---|---|

| PET-500 | 500–800 | ≥90% | 2–4 mm | 100–120 | 380V 50Hz |

| PET-1000 | 800–1500 | ≥90% | 2–4 mm | 150–180 | 380V 50Hz |

| PET-2000 | 1500–2500 | ≥90% | 2–4 mm | 200–250 | 380V 50Hz |

| PET-4000 | 2500–4000 | ≥90% | 2–4 mm | 280–350 | 380V 50Hz |

* Specifications may vary based on raw material condition and customer requirements.

Brief Description of Pelletizing Process

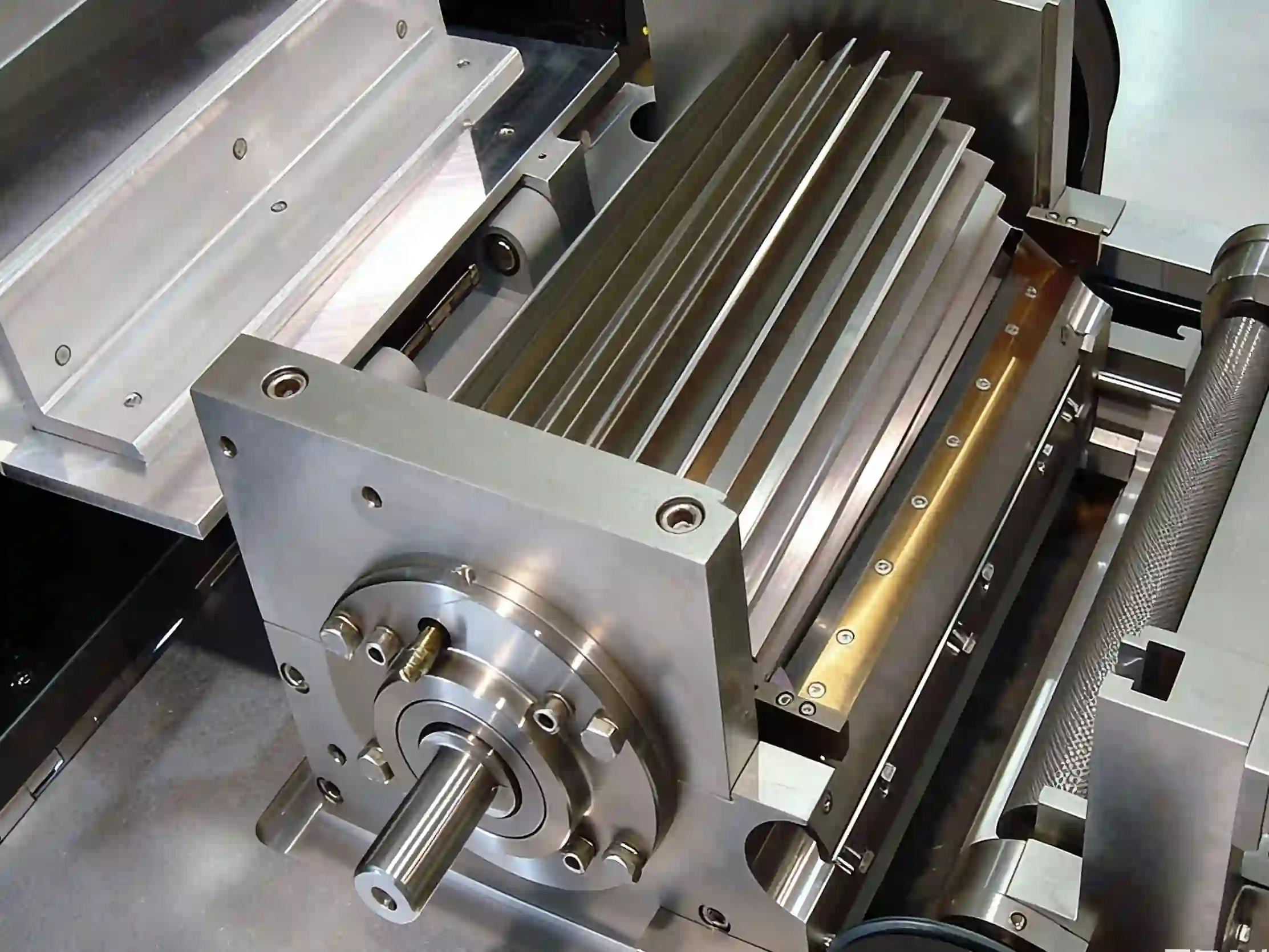

Pelletizing Line Detail Photos

Feeder Unit

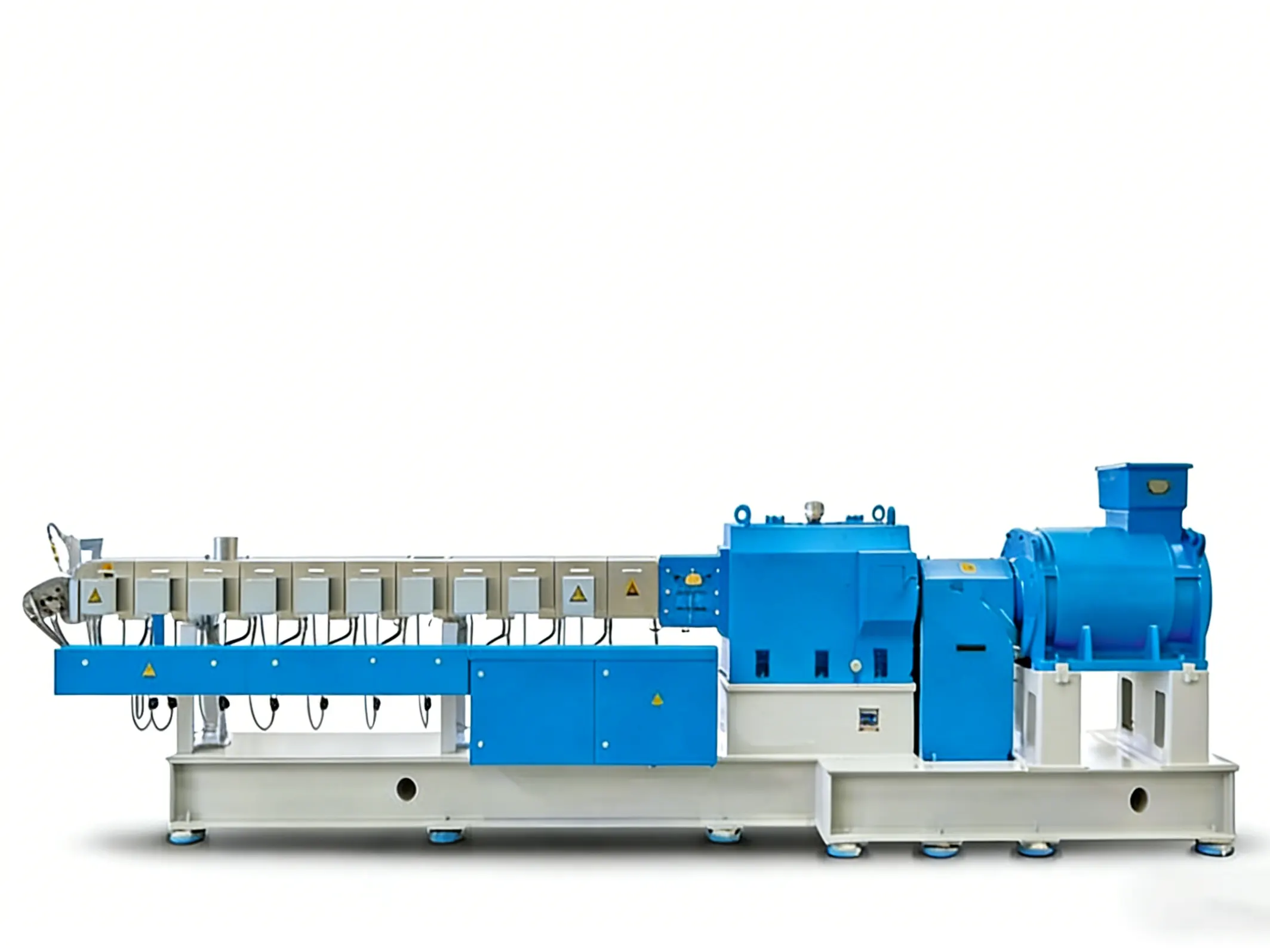

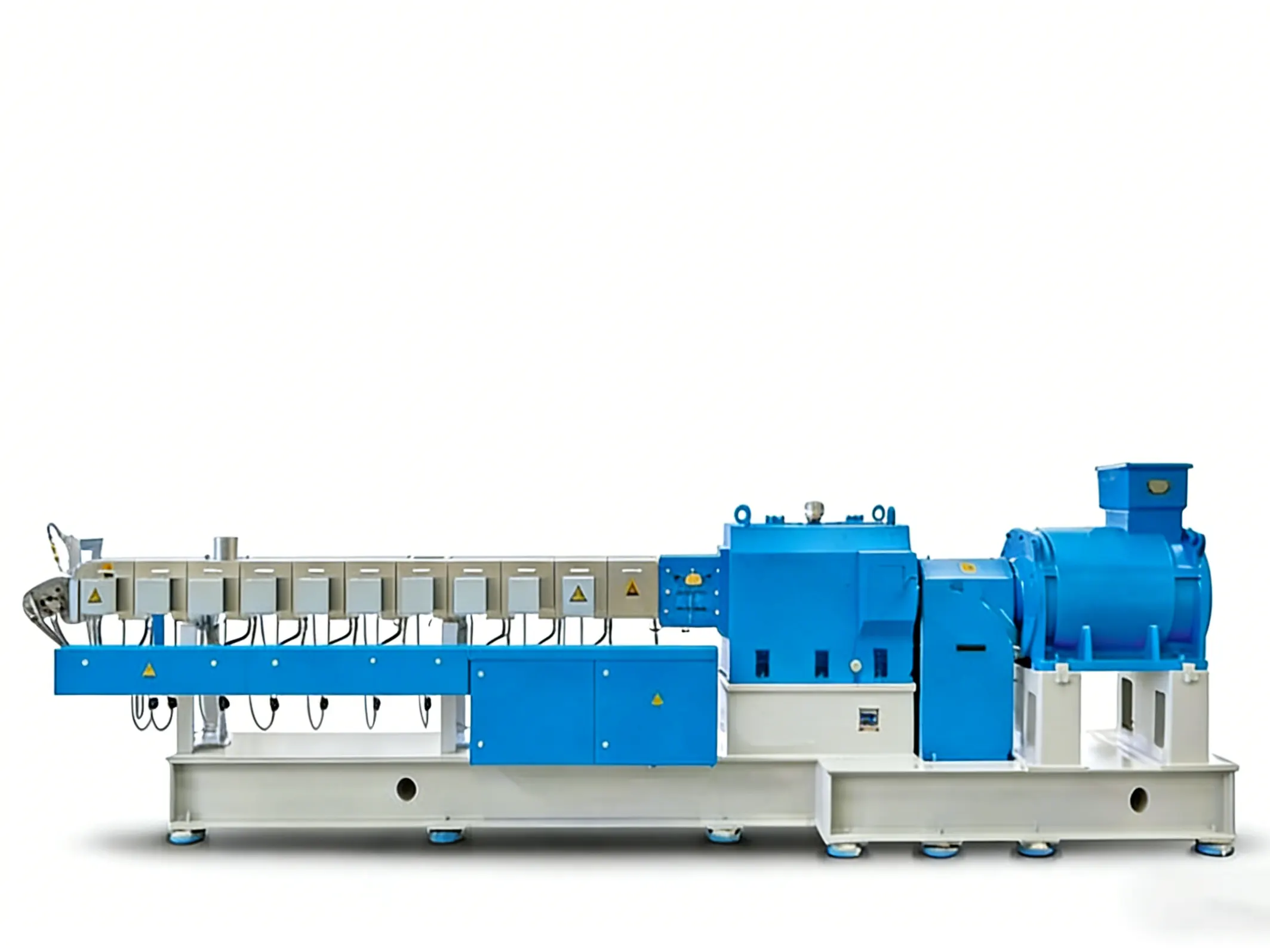

Extruder Unit

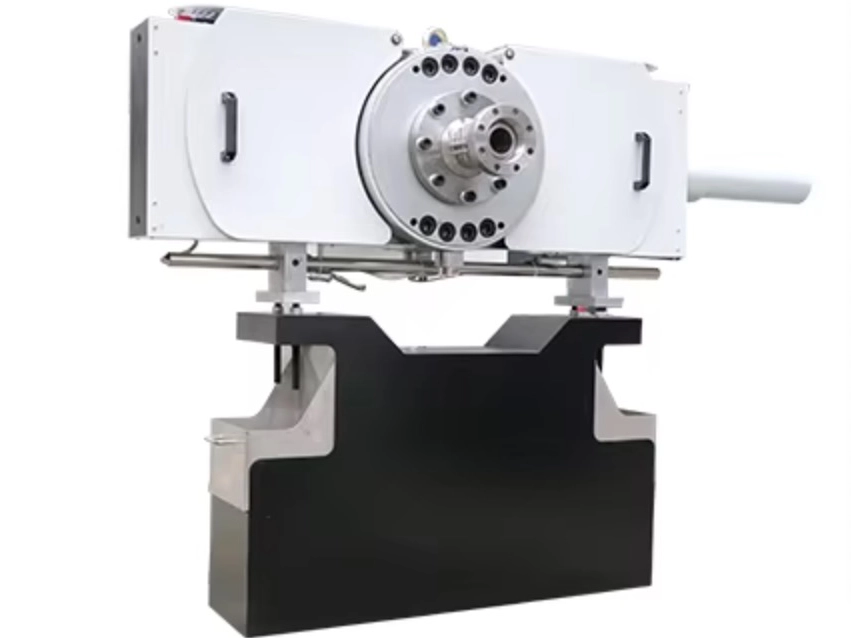

Filtration Unit

Strand Pelletizer

Air Cooling Conveyor

Classifier

Silo

Control Cabinet

Complete PET Flakes Pelletizing Line in Operation

Watch our PET flakes dedicated pelletizing line running at full capacity. See how we process PET flakes into high-quality rPET pellets with IV retention for food-grade and fiber applications.

Request A Free Quote

We'd Like To Work With You. Get a customized solution for your pelletizing project.

15+ Years Experience

Professional plastic recycling solutions

50+ Countries Served

Global installation and support

24–48h Response

Fast engineering support

Get Your Free Quote

Tell us your material and capacity — our engineers will recommend the right configuration.