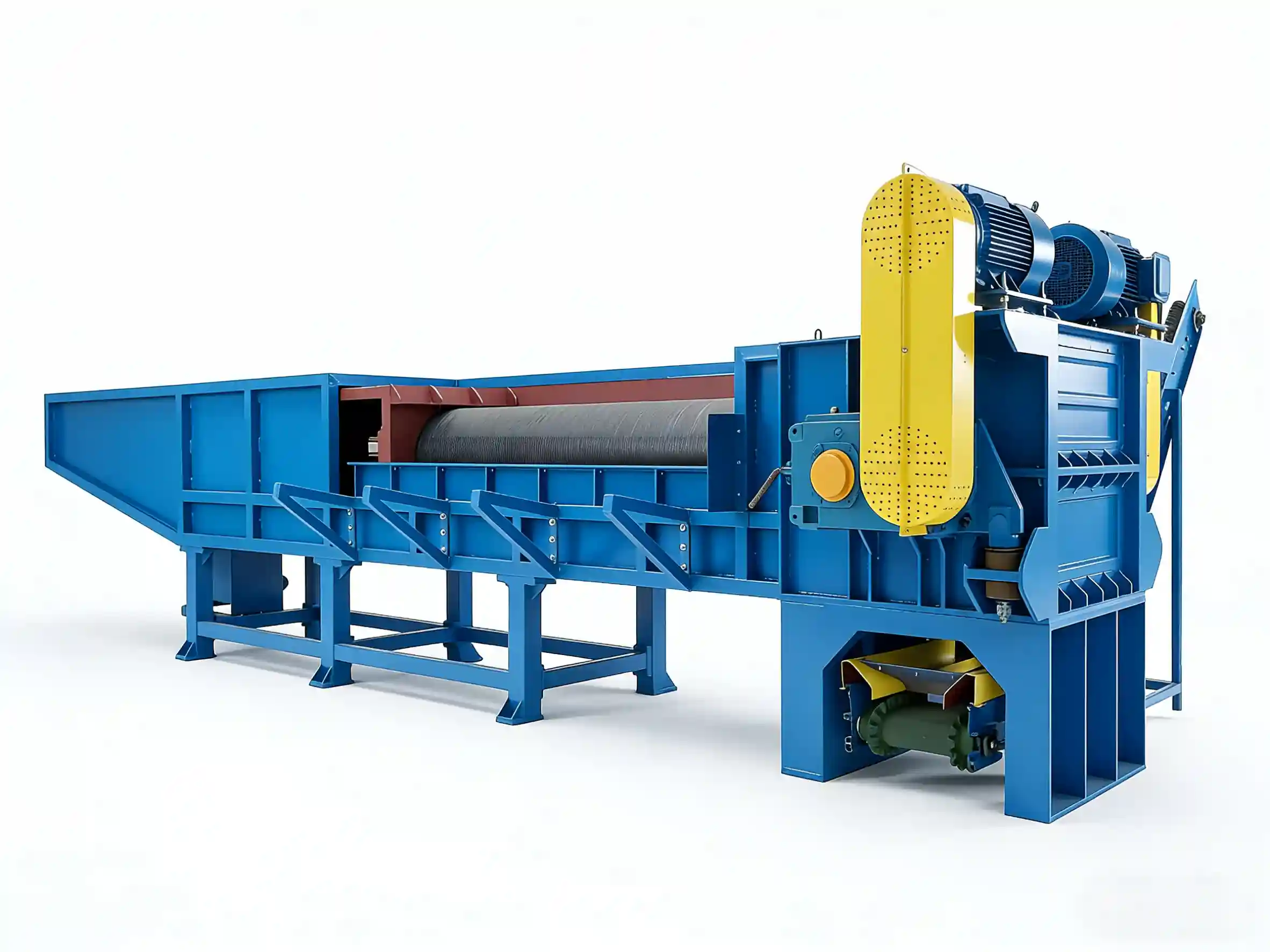

Double Shaft Shredder for Plastic Recycling

Our double shaft shredder delivers high torque and efficient size reduction for bulky plastics, containers, films and mixed waste. Robust twin-shaft design ensures low-speed, high-torque shredding with low noise and long blade life, ideal for the first stage of plastic recycling lines.

Product Overview

The double shaft shredder is built for primary size reduction. Two counter-rotating shafts with hooked blades grab, tear and shred bulky items such as bottles, containers, drums, pipes and film rolls into uniform flakes. Applications include rigid plastic (HDPE, PP, PVC), film and bags, mixed waste, wood, light metal and e-waste pre-treatment.

Gangsu double shaft shredders are designed for 24/7 operation with easy maintenance, reversible blades and durable construction. Options include hydraulic drive, hopper design and integration with conveyors or downstream equipment.

Application & Raw Materials

Mixed Plastic Waste

Mixed Plastic Waste

Rigid PP / HDPE

Rigid PP / HDPE

PE / PP Film

PE / PP Film

PET Bottles & Containers

PET Bottles & Containers

Key Features

Twin-Shaft Design

Two counter-rotating shafts with hooked blades for efficient grabbing and shredding of bulky items.

High Torque Output

Low-speed, high-torque operation reduces wear and noise while maintaining reliable throughput.

Reversible Blades

Extend blade life with reversible cutting edges; easy maintenance and replacement.

Robust Construction

Heavy-duty housing and drive system for 24/7 operation in demanding recycling environments.

Adjustable Output

Blade gap and screen size can be adjusted to control output particle size for downstream processes.

Easy Integration

Designed to connect with washing lines, granulators and pelletizing systems.

Technical Parameters

| Model | Capacity (kg/h) | Motor Power (kW) | Feeding Size (mm) | Output Size (mm) | Machine Weight (kg) |

|---|---|---|---|---|---|

| GSS-800 | 200–400 | 22×2 | ≤800×600 | 20–50 | ~2800 |

| GSS-1000 | 400–700 | 30×2 | ≤1000×700 | 20–50 | ~3800 |

| GSS-1200 | 700–1200 | 37×2 | ≤1200×800 | 20–50 | ~5200 |

| GSS-1500 | 1200–1800 | 45×2 | ≤1500×900 | 20–50 | ~6800 |

| GSS-2000 | 1800–2500 | 55×2 | ≤2000×1000 | 20–50 | ~9500 |

* Parameters vary with material and configuration. Contact us for a detailed proposal.

Machine Details

Twin Rotors

Two counter-rotating shafts with hooked blades for efficient grabbing, tearing and shredding of bulky plastics.

Dual Motor Drive

Dual motor configuration delivers high torque at low speed for efficient size reduction.

Blade & Screen

Reversible rotor knives and interchangeable screens for different output sizes and materials.

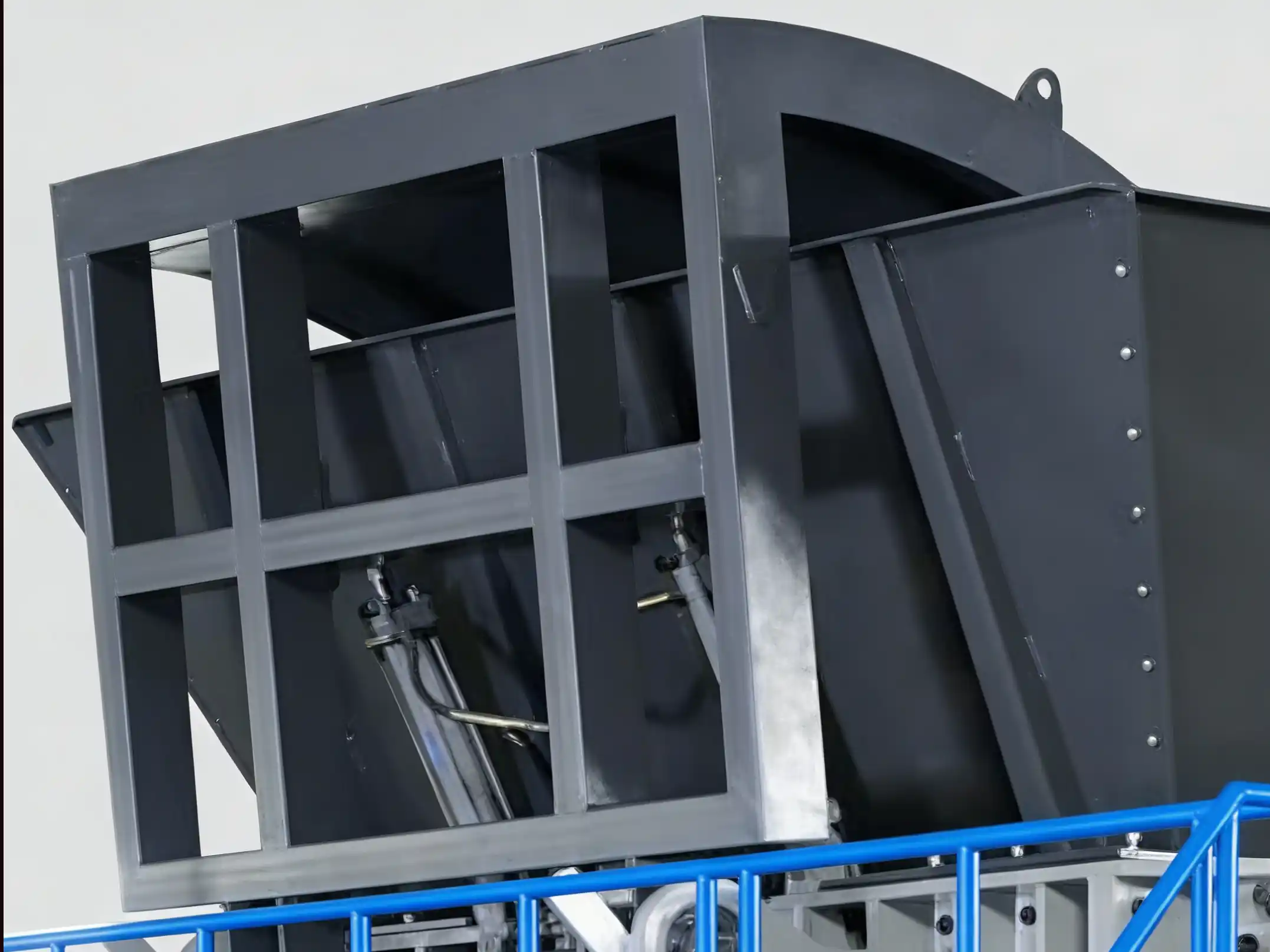

Hopper & Feeding

Optimized hopper design for safe feeding; hydraulic ram and conveyor options available.

FAQ

What is the difference between double shaft and single shaft shredders?

Double shaft shredders use two counter-rotating shafts for higher throughput on bulky items like bottles, drums and film rolls. Single shaft shredders offer more precise output control. Choose double shaft for primary reduction of large rigid plastics; single shaft for washing lines and extrusion.

What materials can the double shaft shredder process?

Our double shaft shredder handles rigid plastics (HDPE, PP, PVC), film and bags, mixed waste, wood, light metal and e-waste pre-treatment. Blade gap and screen size can be adjusted for your material and desired output.

Can it integrate with washing and pelletizing lines?

Yes. The double shaft shredder is often used as the first stage before washing, granulating or pelletizing. We can design the complete line and provide integration support.

About Us

Gangsu designs and manufactures plastic recycling machinery, from shredding to pelletizing, for customers worldwide.

Why Us

Robust machines, proven process design and responsive support so your line runs reliably and delivers quality output.

Our Service

Installation, training, spare parts and aftersales support to keep your recycling line running at peak performance.

Get a Quote

Tell us your material, capacity and site conditions. We’ll propose a solution and a detailed quote.

Customer Case