PET Bottle Washing Recycling Line

Our PET bottle washing recycling line is a complete solution designed to process post-consumer PET bottles into high-purity PET flakes. The line integrates all critical processes – from bale breaking to final flake drying – ensuring consistently clean output suitable for fiber, sheet, and food-grade applications.

- Capacity: 500–5000 kg/h

- Output Purity: ≥99.5%

- Food-Grade Ready

Related Information List

Baled PET Bottles

Clean PET Flakes

Hot Wash System

Label Removal

Production Line Information Table

| Capacity(kg/h) | Power(kw) | Size(m²) | Staff | Qty of steam(kg/h) | Compressed air(m³/min) | Water(m³/h) |

|---|---|---|---|---|---|---|

| 500 | 220 | 400 | 8 | 350 | 4 | 1 |

| 1000 | 500 | 750 | 10 | 500 | 10 | 3 |

| 2000 | 700 | 1000 | 12 | 800 | 15 | 5 |

| 3000 | 900 | 1500 | 12 | 1000 | 15 | 6 |

| 4500 | 1000 | 2200 | 16 | 1300 | 18 | 8 |

| 6000 | 1200 | 2500 | 16 | 1800 | 18 | 10 |

* Specifications may vary based on raw material condition and customer requirements. Contact us for customized solutions.

PET Bottle Washing Recycling Line Process Flow

Bale Breaker

Bale Breaker

Trommel

Trommel

Label Remover

Label Remover

Crusher

Crusher

Hot Washer

Hot Washer

Float-Sink

Float-Sink

Dryer

Dryer

Washing Line Machine Modules

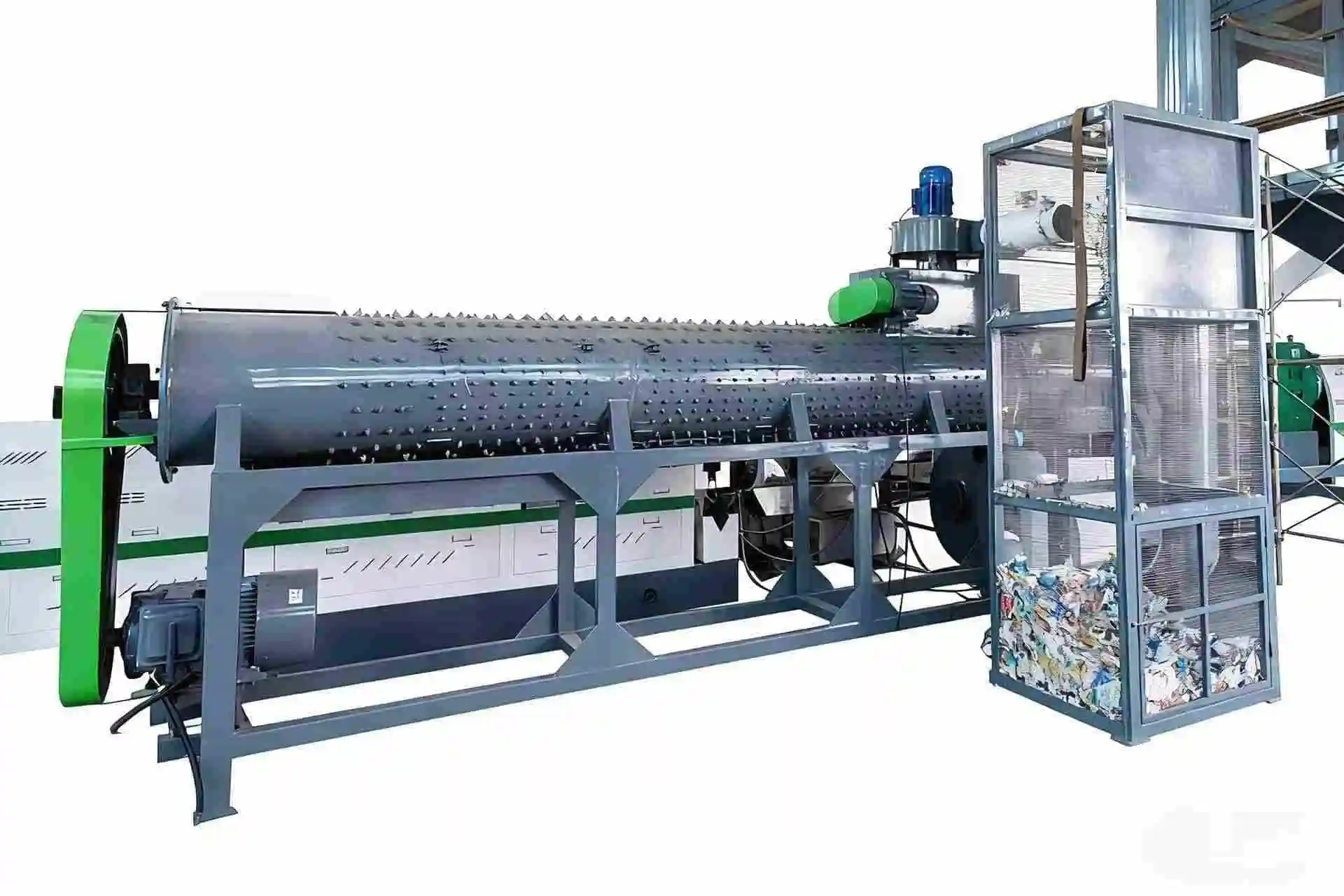

Bale Breaker

Opens compacted bales of PET bottles for processing

Trommel Screen

Removes dirt, debris and small contaminants

Label Remover

Efficiently removes labels from bottles

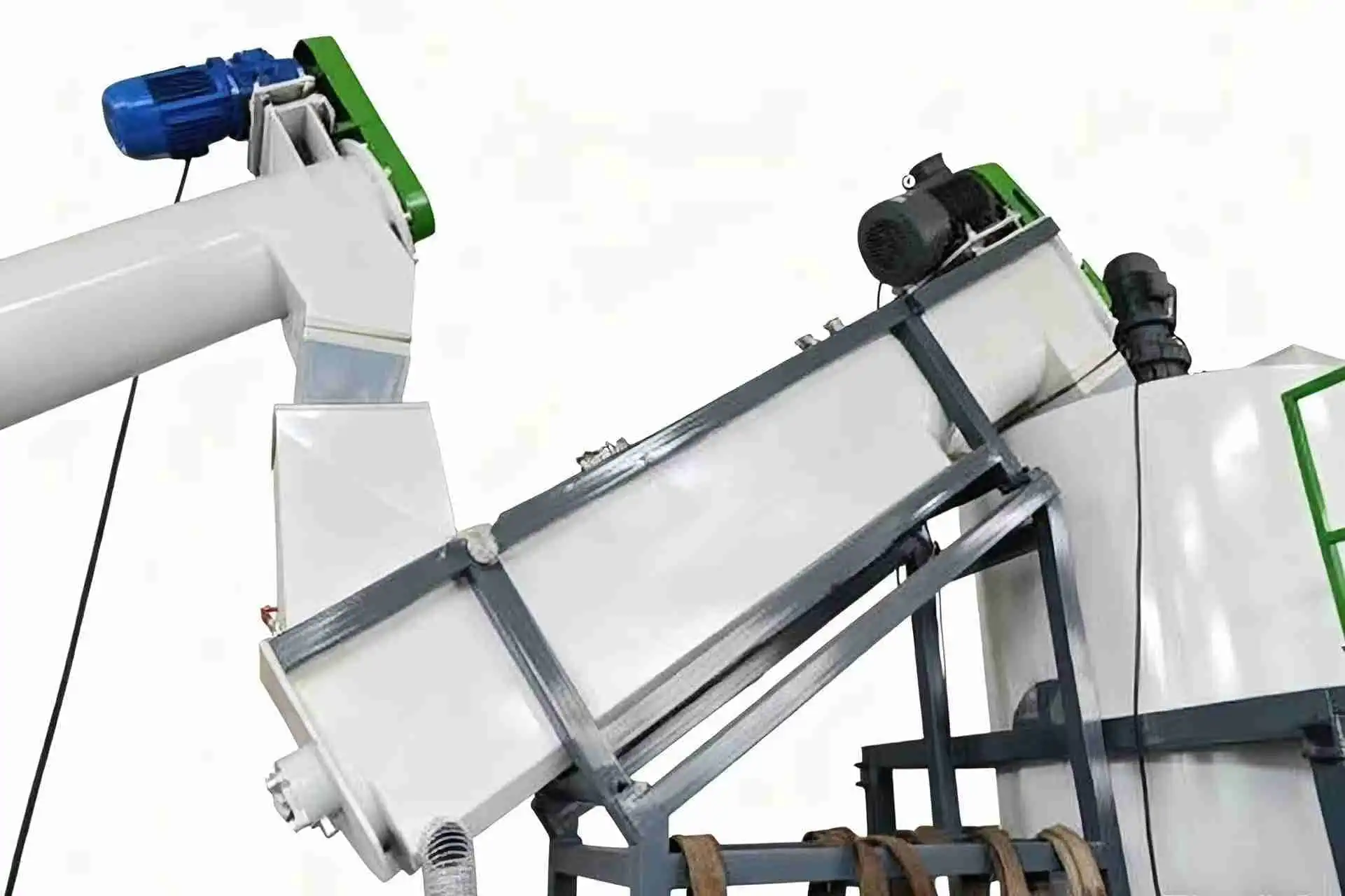

Wet Crusher

Crushes bottles into uniform flakes with water

Hot Washer

Deep cleaning with hot water and caustic solution

Friction Washer

High-speed friction cleaning for stubborn contaminants

Float-Sink Tank

Separates PET from PP/PE caps and labels

Centrifugal Dryer

Removes moisture from washed flakes

Thermal Dryer

Final drying with hot air circulation

Zig-Zag Classifier

Air separation for label and film removal

Storage Silo

Buffer storage for clean PET flakes

Control System

PLC-based automation with touchscreen HMI

Complete PET Bottle Recycling Line in Operation

Watch our PET bottle washing line running at full capacity. See how we process baled PET bottles into clean, high-purity flakes ready for fiber, sheet, or bottle-to-bottle recycling applications.

Talk to EngineerGet a Preliminary Solution

Tell us your material and capacity. Our engineers will advise the right recycling line.